Dryer-Pulveriser

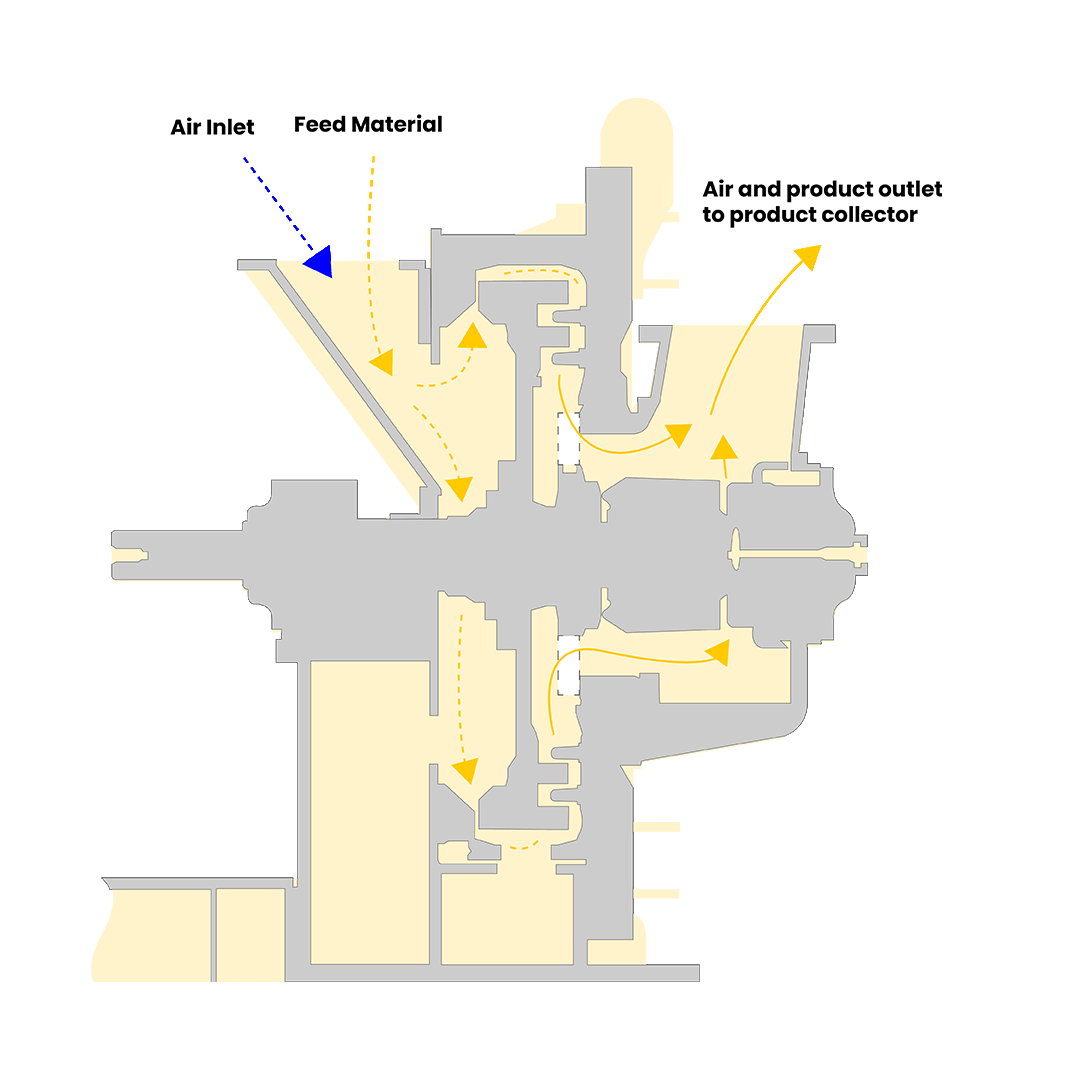

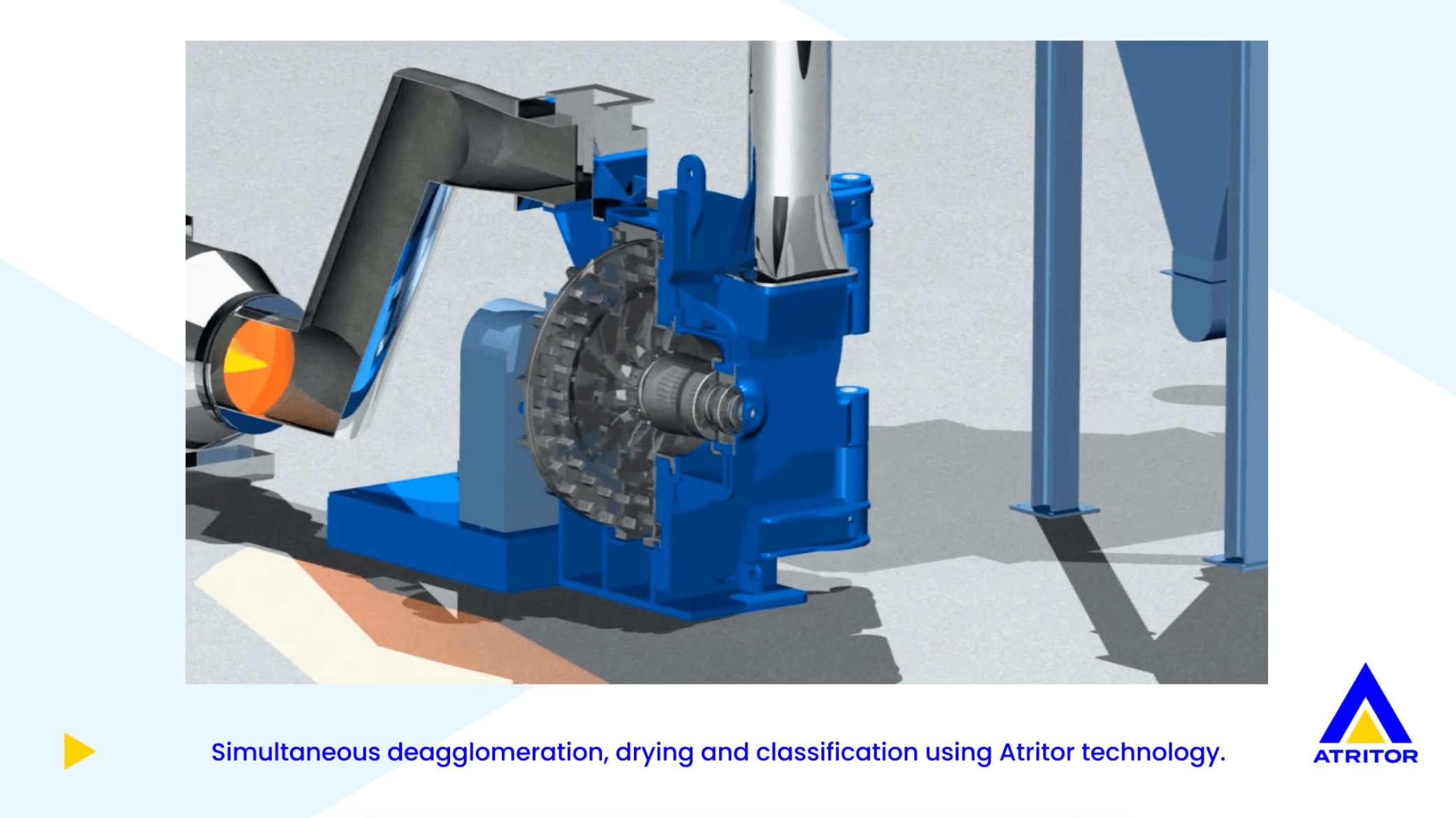

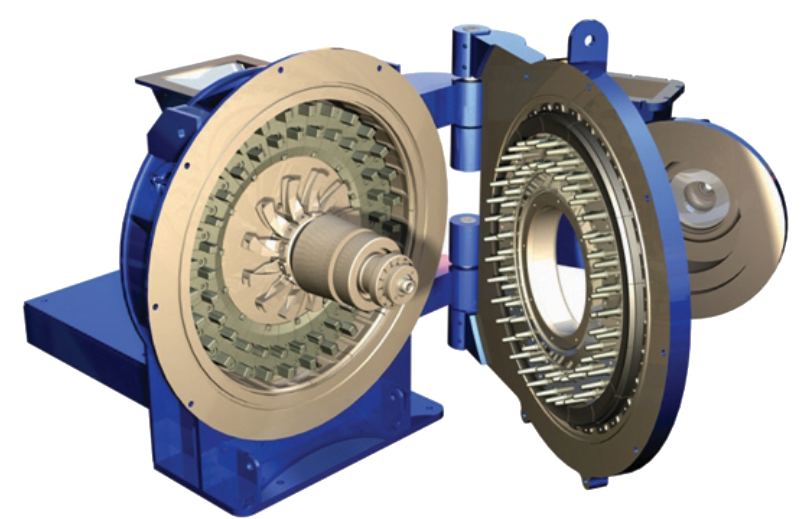

The Atritor Dryer-Pulveriser has been in continuous manufacture for over 90 years. It has a unique design with pulverising occurring predominantly by attrition.

The mill is a very compact air-swept flash dryer and temperature differentials of over 500°C ensure high evaporative capacity and thermal efficiency.

Internal wear parts are manufactured from specially-formulated abrasion resistant irons produced in our own foundry. They are extremely quick and easy to change through the hinged door of the mill.

The size of the feed can be up to 50mm with grinding capacities as high as 8000kg/hr.

The mill incorporates an integral product particle size controller for consistent product quality, which, unusually, is unaffected by processing rate.

Want to know more details about the Dryer-Pulveriser?

A full technical data sheet is available, please click on Talk To us and complete the enquiry form and we will email it to you