Materials & Applications

We have a database of over 500 categories of material and thousands of test results. Accumulated over 75 years, they provide detailed insight into the characteristics and performance of materials.

Material Types

Up to 95% moisture and particle sizes of up to 50mm.

Sludges, slurries, filter cakes, precipitates, powders, fibres, flakes, granules and recycled material.

Applications Tailored solutions

We have the technical expertise to process materials using single or multi-stage operations to ensure products meet your exact specifications.

Drying

Our drying technologies can reduce feeds from 95% moisture to less than 1%. Our plants provide evaporative rates up to 8,000 kg/hr.

Designing a drying process requires recognition of the characteristics of a material, in particular how it may be adversely affected by heat.

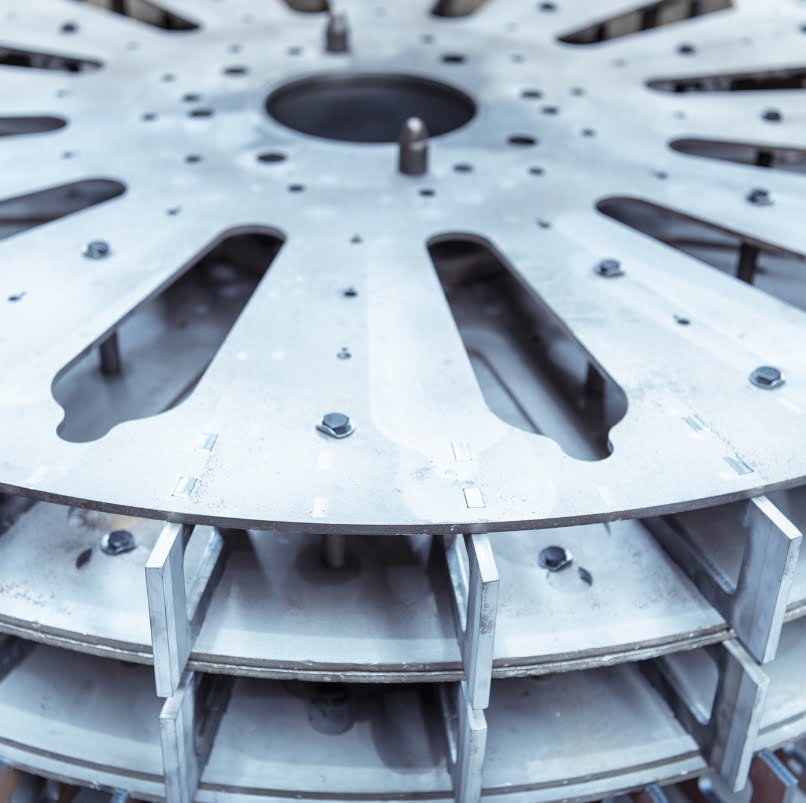

Fine Milling

Our range of equipment can mill a wide range of materials to a mean particle size as low as 20 microns.

Depending on the material, our machines can achieve a much finer powder. With a combination of deagglomeration and milling, we can get down to less than 5 -10 microns.

Deagglomeration

Used for breaking down large clusters or agglomerates of particles into smaller, individual particles.

Particularly useful when it is essential to have consistent and uniform particle sizes for optimal product performance and quality.

Classifying

For applications where a tightly controlled particle size distribution or top-size is required, or when there is a need to remove impurities.

A classifier can be an integral part of a mill, operate in-line with a mill or function as a separate circuit.

Tailored solutions for the reclamation of fly ash.

Download to learn more