Plant Process Solution

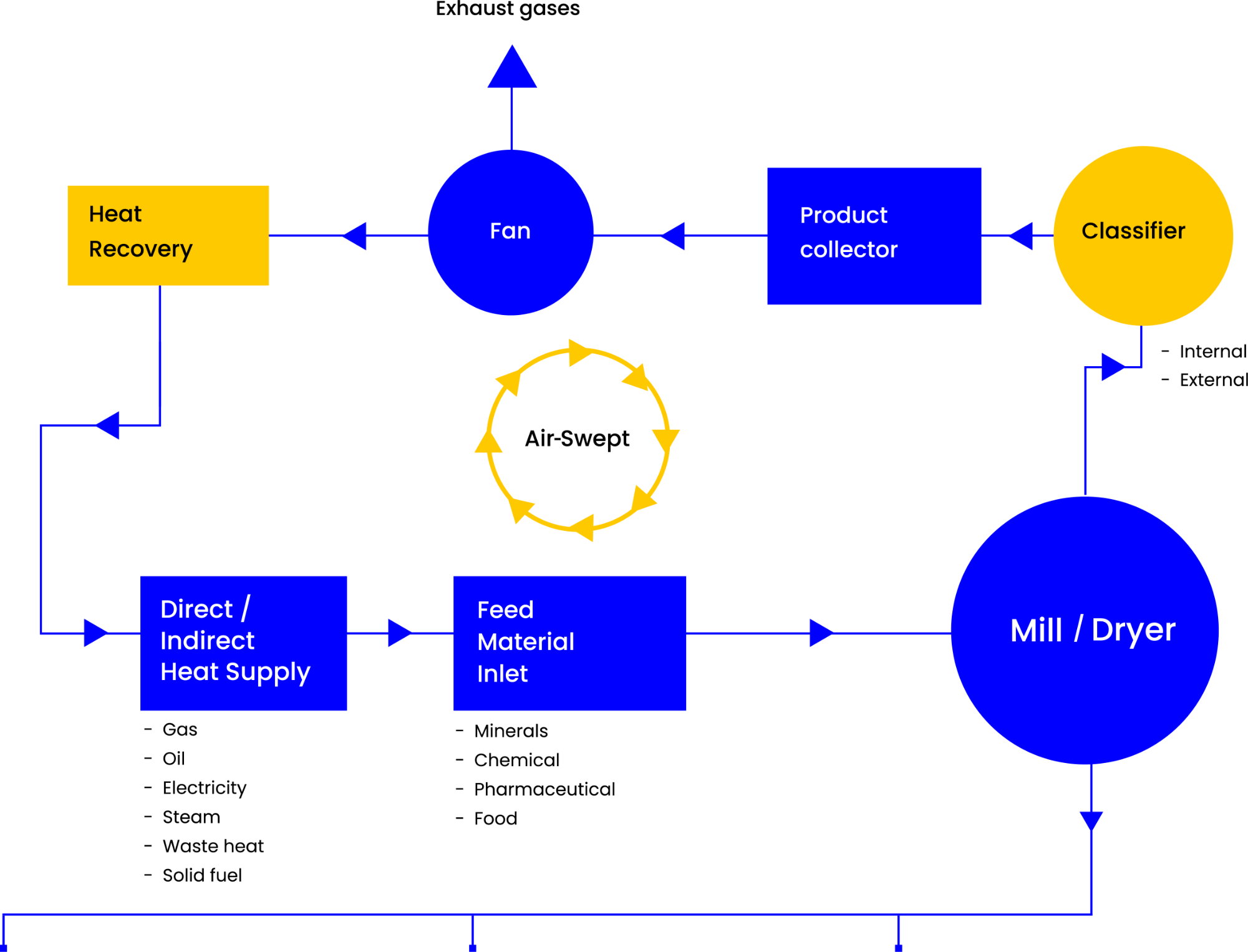

All Atritor plants include an air-swept unit and material is conveyed through the system in an air stream.

All Atritor plants include an air-swept unit, where material is conveyed through the system in an air stream.

Feed material is metered into the inlet air stream using a variety of variable speed devices depending on material character. After the process operation the finished product is discharged from the drying milling unit and carried in the air stream to a cyclone and / or reverse jet bag filter.

Mill / Dryer solutions

Cell Mill

- Simultaneously dries and mills to a super fine powder with tightly controlled particle size distributions

- Capacities range from 50kg/h to 15t/h

- Inlet temperature up to 400°C, outlet temperature to suit final product moisture

- Evaporative rates up to 3,000kg/h

- Slurry injection, classification, coating, surface modification and hygienic options available

Dryer-Pulveriser

- Simultaneously dries and mills minerals, chemical and filter cakes

- Capacity range 50kg/h to 20t/h

- Inlet temperature up to 500°C, outlet temperature to suit final product moisture

- Evaporative rates up to 4,000kg/h

AST Dryer

- Excellent for producing relatively coarse products at high capacities

- Inlet air temperature up to 600°C, outlet temperature to suit final product moisture

- Suitable for feeds of high residual moisture

- Evaporative rates up to 7,000kg/h