Fine milling

Fine milling is a process used to grind materials into very small particles. Atritor fine milling processes can generate a mean particle size as low as 20 microns. Depending on the material, we can achieve less than 5-10 microns with a combination of deagglomeration and milling.

The fine milling process

The process is typically used to reduce the size of particles in various materials, including minerals, metals, ceramics, and food products.

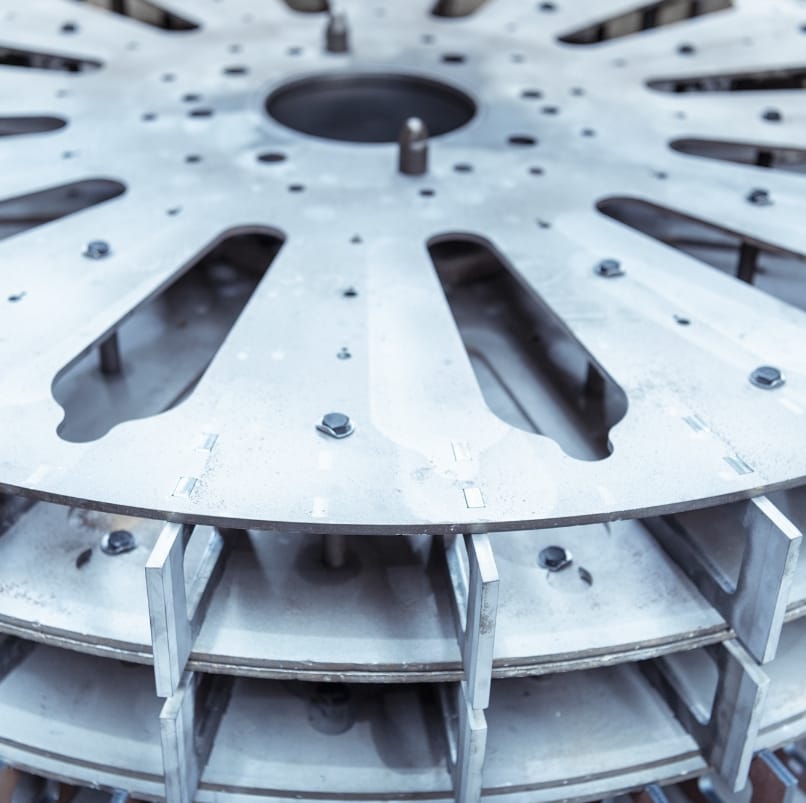

Fine milling machines use mechanical energy to break down the material into fine particles. The process typically uses a rotating disk or rotor with a series of hammers or blades attached to it. The raw material is fed into the machine, and as the rotor spins, the hammers or blades strike the material, breaking it down into smaller particles. Once the material has been milled to the desired particle size, it is typically screened or sifted to remove any over or undersized particles before the final product is ready for use.

Fine milling applications and methods

Fine milling is used for a wide range of applications, including:

- Mineral processing

To grind minerals such as gold, silver, copper, and iron ore into very fine particles for use in a variety of industrial processes. - Pharmaceuticals

To grind active pharmaceutical ingredients into very fine powders for use in tablets, capsules, and other pharmaceutical products. - Food production

To grind grains and other food ingredients into very fine powders for baking, confectionery, and other products. - Pigment production

To grind pigments such as titanium dioxide and other colourants into very fine particles for use in paint, ink, and other coatings.

There are several types of fine milling machines, each with unique characteristics and advantages. Atritor fine milling machines include

The Cell Mill, which uses high-speed rotor blades to break down the material into smaller particles. The material to be milled is fed into the machine, and as the rotor blades spin, they strike the material, breaking it down into smaller particles. The Cell Mill is typically used to grind materials with a high moisture content or are tough to grind.

The Dryer-Pulveriser – this machine uses a combination of high-speed rotor blades and hot air to break down the material into fine particles. The material to be milled is fed into the machine, and as the rotor blades spin, they strike the material, breaking it down into smaller particles. The hot air used in the process helps dry the material, making it easier to grind. The Dryer Pulveriser is typically used to grind materials with a low moisture content or are relatively soft.

The Micronizer, uses high-speed jet streams to break down the material into smaller particles. The raw material is fed into the machine, and as the jet streams pass through the material, they strike it, breaking it down into smaller particles. The Micronizer is typically used to grind heat-sensitive materials or materials that are difficult to grind using other methods.

The benefits of fine milling

There are many benefits to the fine milling process, including

- The increased surface area of the material, which can improve its reactivity and solubility.

- Improved material flow properties, making it easier to handle and transport.

- Increased product purity; the fine milling process can remove impurities from the raw material, increasing its purity and improving its quality.

- Increased production efficiency by reducing the amount of energy required to grind the material and by increasing the final product yield.

- Increased cost efficiency through lower energy requirements and increased final product yield

Ultra-fine milling

Atritor machines can be configured for ultra-fine milling, where powders produced are typically smaller than 10 microns in size.

This process can be done using a variety of different types of mills. The specific mill used will depend on the type of raw material being ground and the desired particle size.

Ultra-fine milling is commonly required in pharmaceutical, chemical, and mineral industries to create high-purity powders with precise particle size distributions. It can also be used to improve the efficiency of chemical reactions, increase the bioavailability of drugs, and improve the properties of certain materials.

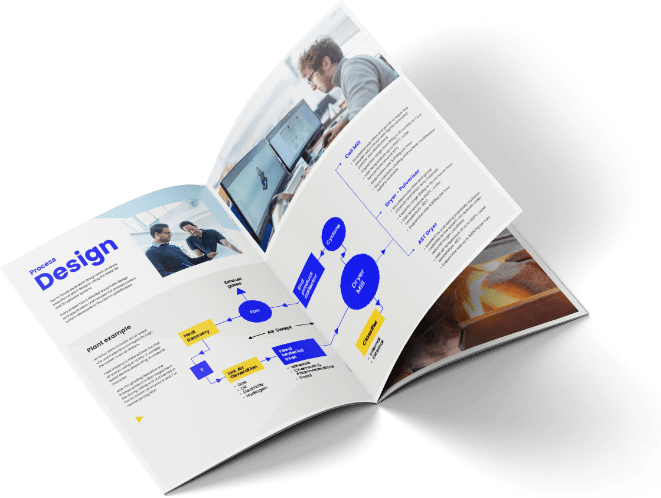

How can we help you?

We thrive on processing challenges here at Atritor. Our extensive experience in the industry has given us the knowledge to design fine and ultra-fine milling processes that take raw materials and manufacturing bi-products and turn them into value-added products. We have the technical expertise to process materials using single or multi-stage operations to ensure products meet your exact specifications. Read more about the processes we specialise in using the links below, or get in touch with our team and see how we can help.

Solving materials processing challenges

Download to learn more