Dry Fractionation of Pulses to Produce High-Quality Protein Concentrate

In the growing pursuit of sustainable nutrition, innovative food milling and processing techniques are transforming the production of plant-based protein concentrates. Simplicity is the name of the game, and Atritor is leading the way with a focus on the dry fractionation of pulses. This streamlined approach is not only revolutionising the industry but also aiding in the creation of high-quality, gluten-free protein concentrates.

Contrasting Methods: Dry Fractionation vs. Wet Enrichment

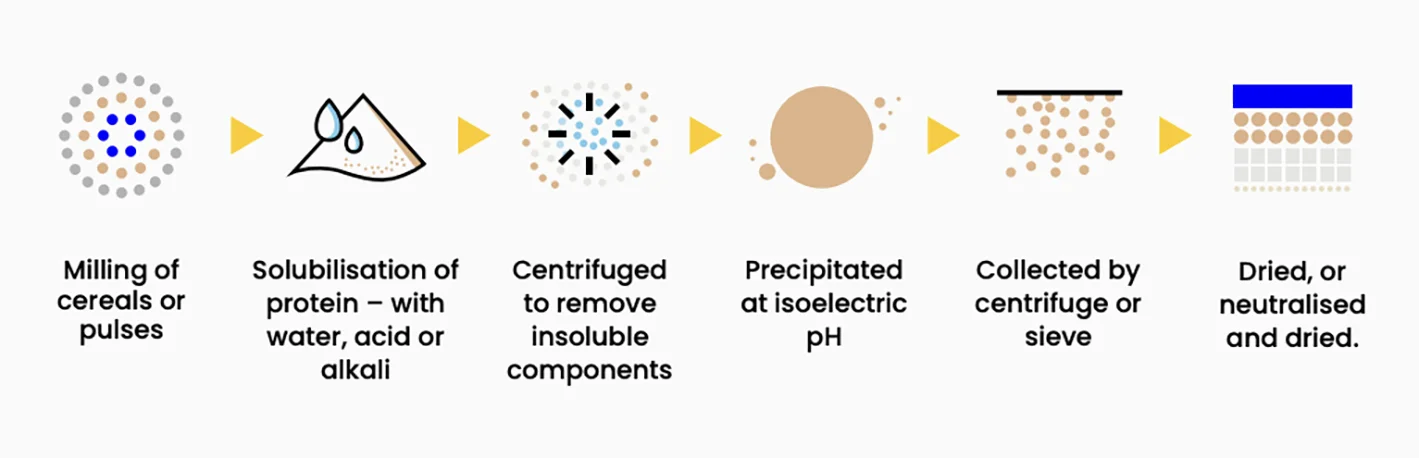

Protein concentrate production is a complex science, involving multiple procedures and techniques. Two of the most well-known methods used in protein concentrate production are dry fractionation and wet enrichment. Both have advantages and drawbacks, but dry fractionation has some distinct edge.

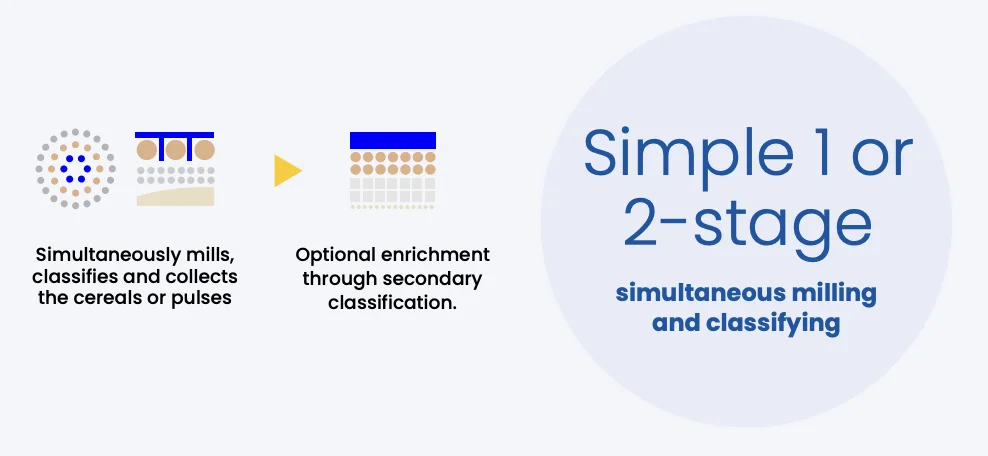

Dry fractionation is an energy-efficient process for producing native fractions from pulses. This method involves milling both the legume and its hull. The hull, once milled, results in a dry coarse fraction that can be repurposed in various products. Following this milling step, various separation techniques, including air classification, sieving, and electrostatic separation, come into play to increase protein purity.

In contrast, wet enrichment calls for the use of water, acid, or alkali for protein solubilisation and precipitation. While it can yield a product high in protein content, the process is often more complex and produces waste products with limited use, making it a less sustainable choice overall.

Dry Fractionation: The Future of Protein Concentrates

Dry fractionation serves as the beating heart of Atritor’s approach to streamlining protein concentrate production. This innovative technique leverages simultaneous milling of legumes and their hulls, effectively yielding protein concentrates and a dry coarse fraction. However, the advantages of dry fractionation don’t merely end at the production of protein-rich concentrates.

One of the unique aspects of this method is the creation of two distinct product streams during the processing. This bifurcation paves the way for businesses to diversify their offerings – a stream of high-protein content to be incorporated in food products and a coarser stream with a lower protein concentration ideal for flour production. By doing so, not only are we able to maximise resource usage, but it also aids significantly in waste reduction.

Our UK-based Pilot Plant serves as the testing ground for our innovative methods. Rigorous in-house tests have demonstrated that our unique dry fractionation technique can be effectively applied to various plulses. This application versatility opens many opportunities for creating novel food products, answering the global call for diversified, sustainable protein sources.

Customisation and Flexibility in Protein Concentrate Production

Innovation is the cornerstone of Atritor’s mission, which reflects prominently in the versatility of our equipment. Our machines are designed with adjustable parameters, enabling us to fine-tune the process according to the specific needs of the materials in use. This adaptability allows our processing solutions to be employed across various feed materials at the production site.

Our commitment to offering a flexible, adaptable solution for protein concentrate production propels us to the forefront of the industry. As businesses seek a one-stop, versatile solution to meet their protein production needs, Atritor stands ready to be their partner of choice.

As the quest for sustainable, plant-based protein sources intensifies, Atritor’s innovative and straightforward approach to protein concentrate production places us at the forefront of this industry. By simplifying the process and focusing on dry fractionation, we’re making it easier for businesses to tap into this burgeoning market and drive a change that benefits our planet.

Here at Atritor, we thrive on process challenges. We have the technical expertise in food milling to process materials using single or multi-stage operations, including dry milling, fine milling, deagglomeration and classification to ensure products meet your specifications. Get in touch with our team and see how we can help.

Simplifying protein concentrate production from plant-based materials

Download to learn more