Mineral milling

Mineral milling, a pivotal process in the realm of mineral processing, is all about breaking down ores into finer particles. This transformative process commences with primary and secondary crushing, reducing large rocks into smaller fragments. The final stage of grinding pulverises the particles into ultra-fine dust in a mineral grinding mill. The reason? Enhancing the surface area of minerals boosts their accessibility for extraction processes.

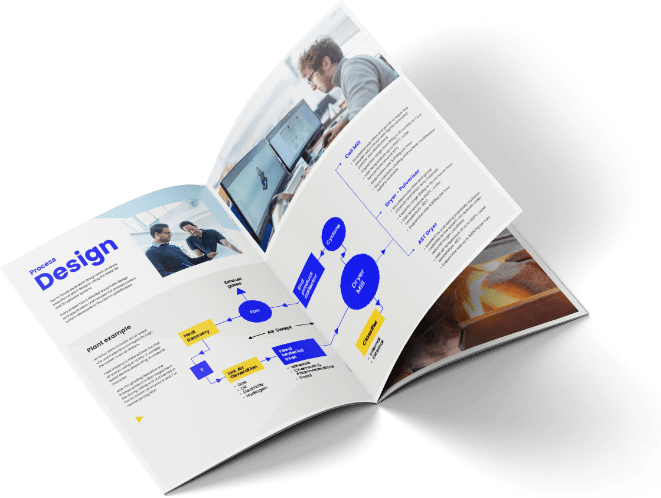

Mineral milling process

A well-design and thought-out solution for mineral processing machinery enables optimal milling, promising improved efficiency, reduced energy costs, and higher yields. In essence, effective mineral milling is essential in unlocking the full potential of minerals during the manufacturing process, making it fundamental for sectors from construction and agriculture to cosmetics and beyond.

Specifying a process for mineral processing

The process we undertake when designing a solution for industrial mineral milling involves a number of important considerations, such as:

- Raw Material Characteristics: The physical and chemical characteristics of the raw mineral, such as hardness, size, moisture content, and chemical composition, have a significant influence on what the process will entail. Our solutions simultaneously dry and mill materials from 95% moisture to less than 0.01%.

- Product Specifications: Ensuring the milling process consistently produces a product that meets the required specifications in terms of size distribution, shape, purity, and other relevant characteristics. This may require a combination of different milling techniques and equipment, depending on specific requirements.

- Throughput Requirements: The milling process is designed to handle the required throughput of the application. This influences the size and number of milling machines and other equipment, as well as the layout of the milling plant.

- Improved Energy Efficiency: Energy consumption is a significant cost in mineral milling, and improving the energy efficiency of processes can significantly reduce costs.

- Environmental Impact: Mineral milling solutions are designed to minimise environmental impacts. This includes minimising dust and noise emissions, reducing water usage, and managing waste products effectively.

- Operational Efficiency and Flexibility: The process is designed to allow efficient operation and maintenance with a minimum of downtime. Our machines are robust, and many plants installed when we started business in 1980 still work reliably today.

- Safety: Mineral milling processes are always designed with safety in mind. This includes both the safety of the operators and the safety of the equipment. Good design can reduce the risk of accidents and equipment damage.

- Investment and Operational Costs: We aim to minimise both the initial investment cost for the milling equipment and the ongoing operational costs. This includes considering the life cycle costs of the equipment, such as maintenance and replacement costs.

- Regulatory Compliance: All mineral processing equipment adheres to industry standards or regulations.

- Integration with Other Processes: In many cases, the milling process will be just one part of a larger process chain. The solution specified takes into account how the milling process fits into this larger chain and aims to optimise the overall process, not just the milling stage.

These are just a few of the key areas we consider when designing an industrial mineral milling process. The specifics depend on the nature of the raw mineral and the intended product, as well as other factors specific to the particular situation.

Materials we work with

We have gained extensive knowledge and test results of thousands of materials over the last 90 years, enabling us to develop bespoke mineral milling solutions for a broad range of materials, each with unique characteristics and processing requirements. This includes clays, coals, and fly ash, along with ground calcium carbonate and gypsum limestone. Our capabilities extend to hard minerals, kaolin, phosphates, and precipitated calcium carbonate (PCC). We also work with versatile talc. Beyond these, our mineral expertise is vast, making our mineral milling solutions comprehensive and adaptable to varied mineral processing needs.

Whatever your process challenge, we have the technical expertise to help. Read more about the process we use to develop bespoke solutions for our clients here.

Mineral milling with Atritor

Our state-of-the-art mineral milling solutions are designed to meet diverse processing needs. We offer solutions for dry milling, fine milling, deagglomeration, and classifying mineral materials, enabling efficient extraction and optimal product quality. Our machinery is engineered for precision and durability, ensuring consistent performance even in the most demanding milling operations.

Atritor machines provide clients with advanced mineral processing equipment that can be tailored to bespoke solutions depending on the mineral composition and output requirements.

- The Cell Mill is ideal for super fine milling of products.

- The Dryer-Pulveriser is used for coarser materials that are harder or more abrasive.

- The Microniser is particularly suitable for small-capacity applications.

Our project teams work closely with clients to understand the application and identify specific requirements in order to design and build tailored solutions.

Get in touch with our team to discuss your mineral processing challenge or idea.

Solving materials processing challenges

Download to learn more